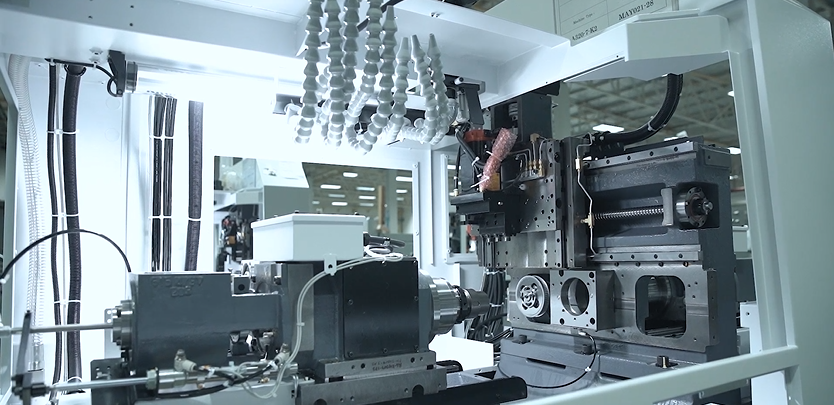

Sliding Headstock Type CNC Automatic Lathes

Achieving optimal component machining for specific needs

through the development of advanced technologies

Excellent for high-precision, high-speed machining and known in the industry for its ease of use.

Provides applications for individual component machining optimized for the customer’s specific needs, equipped with the latest network technologies in addition to NC control technologies that make high productivity possible.

| Model | Max. machining Diameter (mm) | Max. machining Length (mm) | Tool Post | Back Spindle | Secondary Machining |

|---|---|---|---|---|---|

Cincom A20 | ø20 | 165 | gang tool post. | VII | VII |

Cincom B1216E | ø12/ø16 | 135 | gang tool post. | V/VI | V/VI |

Cincom L12VII | ø12 | 135 | gang tool post. | VII | VII |

Cincom L12X | ø12 | 135 | gang tool post. | X | X |

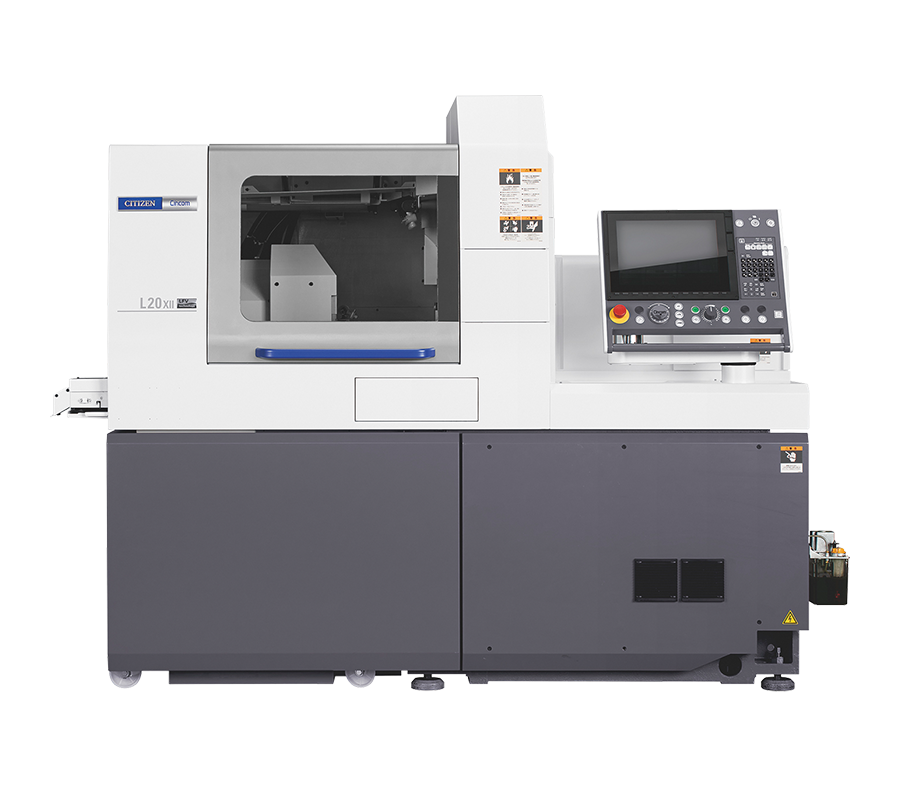

Cincom L20 | ø20 | 200 | gang tool post. | VIII/IX/X/XII | VIII/IX/X/XII |

Cincom L20XIIB5 | ø20 | 200 | gang tool post. | XIIB5 | XIIB5 |

Cincom L32 | ø32 | 320 | gang tool post. | VIII/IX/X/XII | VIII/IX/X/XII |

Cincom D25 | ø25 | 250 | gang tool post. | VIII | VIII |

Cincom M16 | ø16 | 200 | gang tool post. | VIII | VIII |

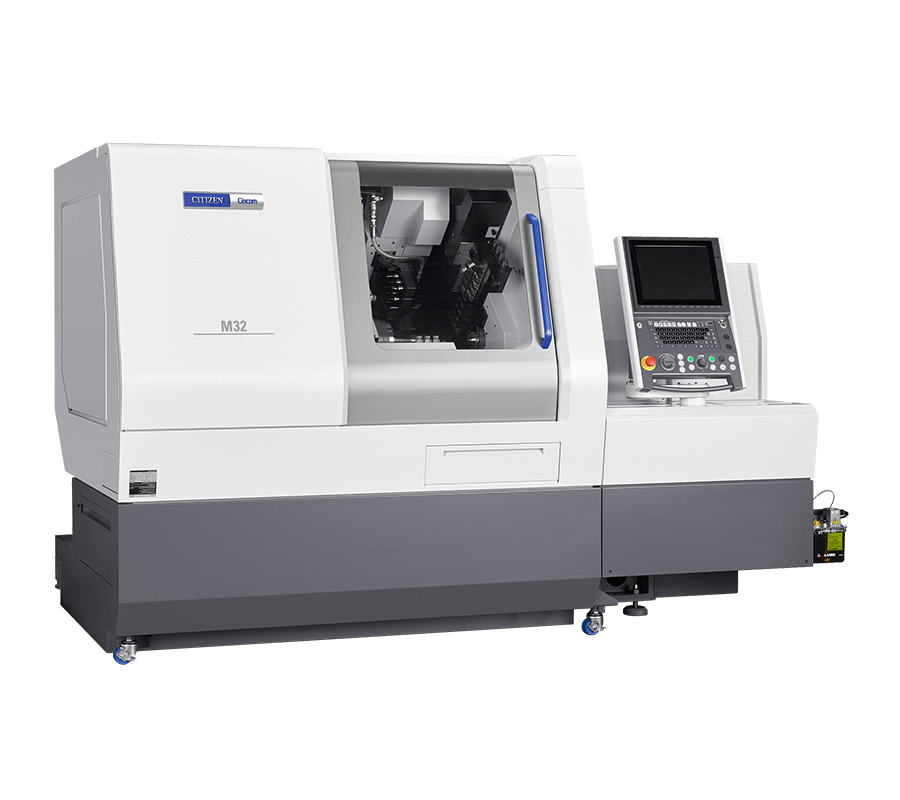

Cincom M32 | ø32 | 320 | gang tool post. | V/VII/VIII | V/VII/VIII |

Cincom R01/04 | ø1/ø4 | 20/40 | gang tool post. | VI | II/VI |