February 3, 2023

CITIZEN MACHINERY CO., LTD.

Shipping of Machines Equipped with LFV Technology Going Well, Topping 5,000 Units Two Months Ahead of Schedule

– Equipped on 13 models, with sales expanding in all areas of the world –

In January, CITIZEN MACHINERY CO., LTD. (Karuizawa Headquarters: Miyota-machi, Kitasaku-gun, Nagano-ken, President: Keiichi Nakajima) broke through the 5,000 mark for the total number of machines shipped with the LFV(low-frequency vibration cutting) technology that successfully resolves various issues relating to chips that have posed problems in cutting work for many years.

To mark this milestone, Citizen Machinery has invited the customer who purchased the 5,000th machine to a commemorative ceremony to be held at the Karuizawa headquarters on February 15.

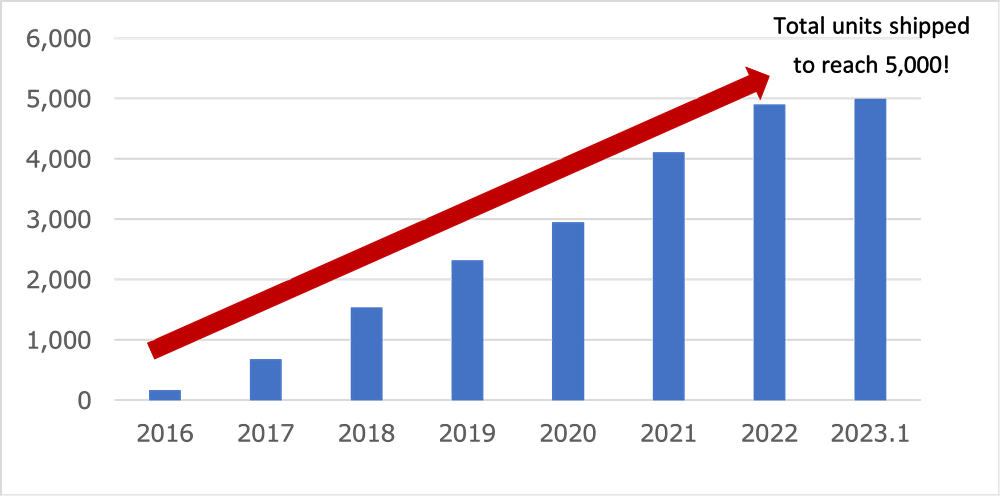

Sales of machines equipped with LFV technology started in 2013, then Citizen Machinery equipped the long-selling Cincom L20 model of sliding headstock type automatic lathe with LFV technology in 2016, and in 2021 they equipped a turret tool post with this technology for the first time on the Miyano ANX42SYY fixed headstock type automatic lathe, expanding the number of models featuring the technology to 13. The cumulative number of units shipped exceeded 4,500 in September 2022, and the 5,000-unit mark was expected to be achieved in March 2023, but it was actually achieved two months ahead of schedule due to sales expansion in all areas of the world.

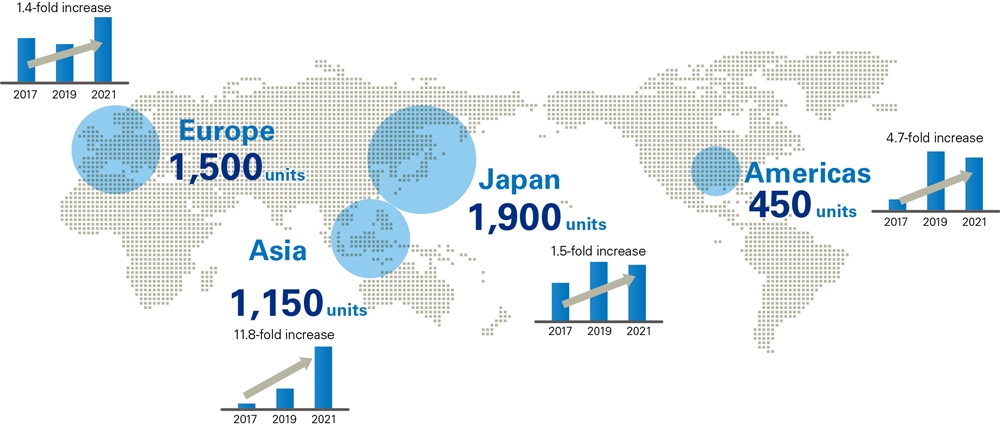

Sales of machines equipped with LFV technology were expanded to Europe and the USA in the fall of 2016, and to Asia in 2017.With the number of customers who want machines equipped with LFV technology increasing worldwide as a result of word-of-mouth recommendations from customers who have actually experienced the advantages of LFV, which we can state as improved productivity (*1) and sustainability factors (*2), and of repeat purchases, the number of units shipped in 2021 was 2.2 times greater than in 2017.

Taking cumulative shipment of more than 5,000 units in the 10th year since the commencement of sales as a new start, Citizen Machinery will continue to make contributions to customers’ manufacturing as pioneers of LFV technology.

(*1) Decreasing the temporary stoppages of production caused by chips

(*2) Decreasing the CO2 emissions generated in the transportation of waste, since the chips are broken up into smaller pieces than those from conventional cutting and therefore occupy a smaller volume

Cumulative Total Number of Machines Shipped with LFV Technology

About LFV Technology

– What is LFV technology?

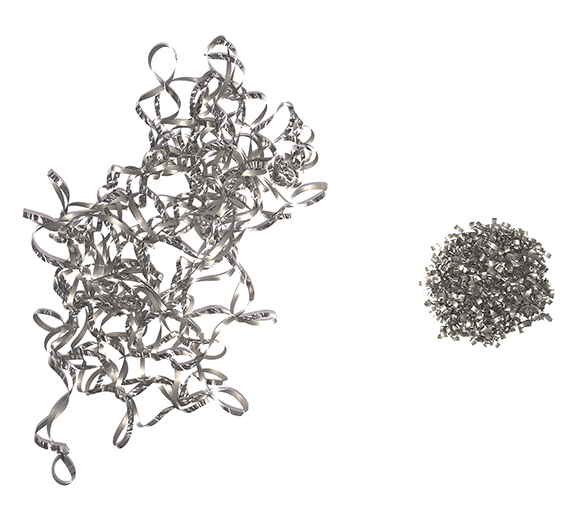

The servo axes are vibrated in the axial direction using a unique control technology whereby cutting is performed while synchronizing this cutting with the rotation of the spindle, and chips are broken up into smaller pieces by providing “air-cutting” time where the tool makes no contact during cutting.

– Effects of LFV technology

(1) Improves the efficiency of small-diameter deep hole machining

(2) Makes it possible to finely break up chips even when turning difficult-to-cut materials, which tends to generate long chips

(3) Prevents scratching of workpiece surfaces

(4) Substantially reduces the volume of chips

(5) Achieves high-precision machining over long periods

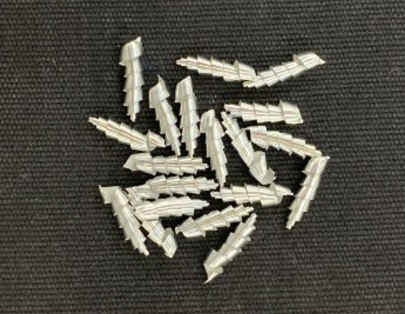

Difference in shape of chips of the same weight (Material: SUS304)

Left : Chips generated by conventional cutting

Right : Chips generated by LFV technology

Wide Range of Machining Possibilities

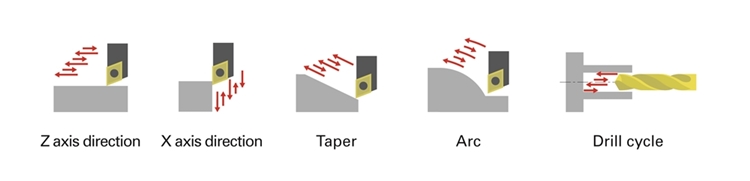

1. Various Machined Shapes Possible Using 2-axis Interpolation with Vibration

CITIZEN MACHINERY’s LFV technology is not just applicable to cutting on a single axis – whether in the horizontal or vertical direction – as it allows two axes to be vibrated and interpolated even during the machining of sections including arcs and slopes (tapers).

Examples from Range of Machined Shapes

2. LFV Modes 1 to 3 Available for Different Machining Issues

The optimum machining method can be selected from 3 modes.

Description of Modes

| LFV mode 1 | When you want to thoroughly break up chips, with difficult-to-cut materials for example Method where the number of vibrations per revolution of the workpiece is specified |

| LFV mode 2 | When a surface speed is required, such as when machining thin workpieces or small-diameter deep holes Method where the amount of workpiece rotation per vibration is specified |

| LFV mode 3 | When you want to break up chips in thread cutting Method where machining is performed while changing the vibration timing every thread cutting pass |

Chips with LFV mode 1

Chips with LFV mode 2

3. Function to Temporarily Stop Vibration during LFV Modes Provided

When programming, vibration can easily be stopped in a particular line where it is not required by inputting “,V0” at the end of that line. This is useful when you want to travel or cut in an LFV mode without vibration, for example during approaches at the rapid traverse rate, or escape movements.

* “LFV” is a registered trademark of Citizen Watch Co., Ltd.