October 7, 2021

CITIZEN MACHINERY ASIA CO., LTD.

Machinery Asia Achieves Cumulative Shipment of NC Automated Lathes

20,000 Units Shipment Memorial Ceremony and New Showroom Opening Ceremony Held

CITIZEN MACHINERY CO., LTD. (Karuizawa Headquarters: Miyota-machi, Kitasaku-gun, Nagano-ken, President: Keiichi Nakajima) will start sales in December 2022 of the Miyano “BNA42SY” fixed headstock type CNC automatic lathe, which will be the first machine with hand scraped slideways to be equipped with its unique LFV (low-frequency vibration cutting) technology that successfully resolves various issues relating to chips.We will exhibit this product at JIMTOF 2022, which will open on November 8, 2022.

Miyano “BNA42SY” Fixed Headstock Type CNC Automatic Lathe Equipped with LFV Technology

- Launch date : December 2022

- Planned monthly production : 10 units

The Miyano “BNA42SY” is a best-selling machine with a 2-spindle/1-turret configuration enabling complex machining, and is capable of stable machining with its highly rigid base and turret.Hand scraped slideways are used on all axes, and equipping the turret with LFV technology on this model makes it possible to resolve various issues relating to chips, even with difficult-to-cut materials like inconel and stainless steel that require rigidity on machines used for machining, helping customers achieve more stable production.

Hand scraped slideways are characterized by sliding surfaces that make contact mediated by an oil film, large contact faces and high rigidity, and by taking sufficient time to verify the effects of vibration on these slideways and resolving the issues discovered, we succeeded in equipping LFV in conjunction with them.

Number of Machine Models Equipped with LFV Technology Increased to 12, to be Further Increased Progressively

Having succeeded in equipping LFV technology with the hand scraped slideways that have been so strongly requested by customers, we will continue to increase the number of machines equipped with LFV.

* Explanation of hand scraped slideways: Broadly speaking, automatic lathes have two slideway mechanisms (mechanisms whereby the machine moves by sliding): “hand scraped slideways” and “roller slideways”.The “hand scraped slideways” have sliding surfaces that make contact mediated by an oil film, leading to the advantages of large contact faces and high rigidity.The “roller slideways” operate by rolling using linear guides and roller guides in their mechanism, leading to the advantages of excellent responsiveness and operability.

About LFV Technology

The servo axes are vibrated in the axial direction using a unique control technology whereby cutting is performed while synchronizing this cutting with the rotation of the spindle, and chips are broken up into smaller pieces by providing “air-cutting” time where the tool makes no contact during cutting.

Effects of LFV technology

- 1. Improves the efficiency of small-diameter deep hole machining

- 2. Makes it possible to finely break up chips even when turning difficult-to-cut materials, which tends to generate long chips

- 3. Prevents scratching of workpiece surfaces

- 4. Substantially reduces the volume of chips

- 5. Achieves high-precision machining over long periods

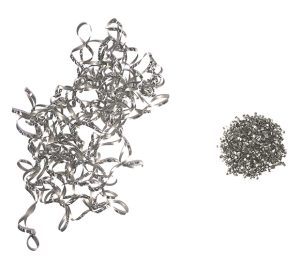

Difference in shape of chips of the same weight (Material: SUS304)

Left : Chips generated by conventional cutting

Right : Chips generated by LFV technology

* “LFV” is a registered trademark of Citizen Watch Co., Ltd.

About LFV Technology

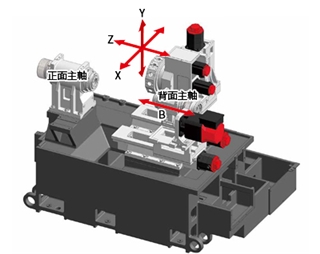

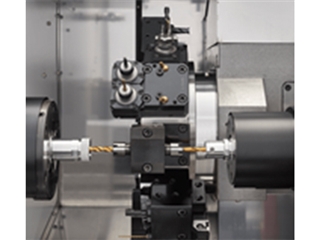

The Miyano “BNA42SY” fixed headstock type CNC automatic lathe is a best-selling machine which, despite its compact size, has a highly rigid base and turret with a 2-spindle/1-turret configuration enabling complex machining.

Main Characteristics of the BNA42SY

1.Base and turret rigidity increased

Rigidity has been increased by a heavier new design for the base, and by adopting hand scraped box slideways on all axes.

2.12-station turret featuring a Y axis and left/right simultaneous machining realize high efficiency and complex machining capability

The 12-station turret equipped with an Y-axis and the capability of simultaneous left/right machining using the front and back spindles, including superimposition machining where the back spindle follows machining at the front spindle, realizes high efficiency including shorter machining time, as well as complex machining capability.

3.Rotary tools mountable at all turret stations for improved multifunctional performance

Since rotary tools can be mounted at all of the 12 stations, multi-functional machining performance has improved.

Major Specifications

| Model | BNA42SY | |

|---|---|---|

| Max. machining diameter of front spindle | Collet | ø42㎜ |

| Power chuck | 6inch | |

| Max. machining length | 100㎜ | |

| Spindle speed | Max.6,000min-1 | |

| Max. chucking diameter of back spindle | Collet | ø34㎜ |

| Power chuck | 4inch | |

| Back spindle speed | Max.5,000min-1 | |

| Axis strokes (feed distances) | X axis | 140mm |

| Y axis | 70mm(+35mm/-35mm) | |

| Z axis | 285mm | |

| Number of stations for mounting tools | 12 (1 turret) | |

| Revolving tool capacity | Max. 12 | |

| Max. drilling diameter by revolving tool | ø10㎜ | |

| Max. tapping diameter for revolving tools (cutting tap) | M8 | |

| Tool size | Turning tool | □20mm |

| Sleeve | ø25mm | |

| Motors | For spindle drive | 11/7.5 kW/5.5 kW (15%/15 min/cont.) |

| For back spindle drive | 5.5/3.7kW(15min/cont.) | |

| For driving rotary tools | 2.8/1.0kW | |

| Required floor space | W2,350 × D1,433mm | |

| Mass | 3,650kg |